Did you ever considering that everything isn’t lined up straight on your boat?

I have heard a lof ot horror stories about maststeps well out of column, masts that are impossible to tune just becauce the shroud fittings is asymmetric or rudders that are not parallell to the centerboard.

Getting inspiration from our professional America’s Cup boat builders in Victory Challenge, I thought I would make a serious effort in lining it all up and bought a laser. Expensive? Not at all! I got one at Home Depot for around 30€, usually being used for putting tiles in your bathroom. The best thing was it had a crosshair beam giving a perfectly horizontal and vertical line.

Getting inspiration from our professional America’s Cup boat builders in Victory Challenge, I thought I would make a serious effort in lining it all up and bought a laser. Expensive? Not at all! I got one at Home Depot for around 30€, usually being used for putting tiles in your bathroom. The best thing was it had a crosshair beam giving a perfectly horizontal and vertical line.

One thing is clear though; It is very hard to have a boat that is perfectly Square everywhere. The key thing must be to have the important Points lined up. Things like rudder/centerboard, mast step, mastcolumn, forestay and shroud fittings.

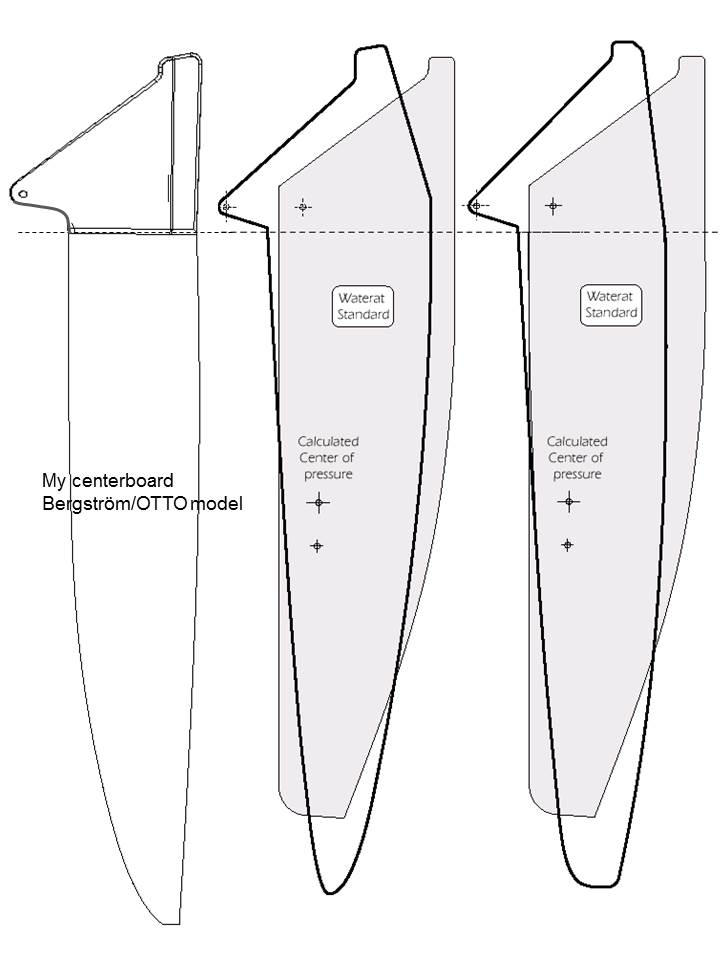

OK, what is it on the boat that I can not really do anything about? Since I am starting with a bare hull, the main component was the centerboard case. I started by putting the centerboard upside down in the centerboard case, fiddled around with different wooden chocks under each rail and used my laser to make sure the centerboard aft edge was vertical.

Perfect, since the laser horizontal beam would Always be level, I could now Move it around and check the other important Points. Taking the centerboard out, I could now check that the hole for the mast at deck level was vertically above the mast step. …or actually the other way around as it would be a lot easier to put the step a bit off axis to make it lining up. Fortunately, mine was straight but the whole exersise will give me a peace of mind and help me go straight to the right things if the mast isn’t straight when starting tuning it.

As I had the boat lined up, I marked up the vertical line for the rudder fittings and fitted the bottom one. However, I will wait and mount the top one when I have both the centerboard and rudder on its fittings in its place.

As I had the boat lined up, I marked up the vertical line for the rudder fittings and fitted the bottom one. However, I will wait and mount the top one when I have both the centerboard and rudder on its fittings in its place.

Next thing was to make sure that the rudder, centerboard, mast and forestay was on one line. Now I put the boat on its transom With the bow sticking straight up the air. Now my neighbors really started looking suspicously across the fence, especially as I did all this completely on my own.

Again I used the laser lining the rudder/centerboard intersection up with the vertical beam. I frankly don’t know what I would have done if it wasn’t straight but luckily the unalignment where within a millimeter or two. As I now had it like this I could use the horizontal beam to mark out where the shrould fitting would go.

Finally, I measured from the centerline out to where the shroud fittings would go just to make sure that the mast is absolutely in the middle between the shrouds.

I am sure there are a lot of ways of doing this but this procedure worked well for me. It was very valuable to have a laser with a crosshair vertical and horizontal beam.

Good luck with lining your boat up. …’cause you don’t want to be out of line?

Once again we are District Champions in the 505. As usual, we sailed in Kullavik just outside the harbour and 6 505s showed up. As we haven’t sailed that much this year, it was especially fun to wind eventually.

Once again we are District Champions in the 505. As usual, we sailed in Kullavik just outside the harbour and 6 505s showed up. As we haven’t sailed that much this year, it was especially fun to wind eventually. Now as we have got the whole boat well fitted out, we look forward to next season. Hopefully we will be able to fit in more of the 505 races.

Now as we have got the whole boat well fitted out, we look forward to next season. Hopefully we will be able to fit in more of the 505 races.