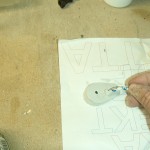

Fitting the new boat out goes forward. It takes a lot of time and thinking to get everything right, even though I have passed the initial hesitation to drill in the shiny new boat. Mainly it is just about puttings blocks and cam cleats at the right place. However, at times you need something to wedge the fittings to get the to properly line up.